This is my archive

Large order for Johan Sverdrup

December 2018

PG/Calder Johan Sverdrup Phase 2 scope of supply includes pump units for scale inhibitor injection, chemical injection, emulsion breaker injection, and MEG injection. All units will be supplied to Aker Solutions and Kvaerner (ASK/JV), a 50/50 joint v...Energy company orders a lightweight, compact, hydraulically driven, high pressure chemical injection package

November 2018

This pump package is designed for use in a Zone 2 hazardous environment on the deck of an offshore service vessel and offshore platforms. With no suitable electric supply in the area this diesel-driven hydraulic system was chosen which enables maximu...Hammelmann High Pressure Technology Symposium

October 2018

Water Jetting Equipment Demonstrations and Presentations Hammelmann will be holding a symposium at their facility in Oelde, Germany, to showcase the latest in waterjetting technology. There will be demonstrations, presentations and equipment on...Lightweight units to suit the needs of the offshore industry

September 2018

For many ageing platforms in the North Sea, decisions are being made to either decommission them or to extend their operational life. Either way, there can be ramifications for the cranes on these platforms. Where a crane’s design life has been reach...A fleet of lightweight, compact air compressors for hazardous environment operation

September 2018

We have recently supplied a fleet of lightweight, compact air compressor units for use in Zone 2 (Group II Category 3 G IIB T3) hazardous environments. The units have a performance of 400 cfm at 10 bar and can operate in ambient temperatures of 50°C....MEG Injection pump package with twin variable stroke pumps

September 2018

Design starts on a MEG injection pump package for use on a North Sea platform. The package will transfer MEG at the required pressure and flow to both topsides and subsea templates during start-up, shut-down, leak/barrier testing, maintenance, and pr...Work starts on MEG pump package for the Nova tie-back to Gjøa Project

July 2018

Rosenberg WorleyParson AS has awarded PG Flow Solutions subsidiary Calder Ltd a contract to supply a MEG pump package to the Nova tie-back to Gjøa Project. The Norwegian EPCI contractor is responsible for the upgrade on the Gjøa platform in the North...Final checks for this robust offshore unit

July 2018

Being prepared for despatch is this high pressure well service and pressure test unit from our MultiJet range capable of pumping up to 168 litres per minute at 690 bar. This shipment satisfies an urgent requirement Halliburton had for a high press...Work Starts on Pump Unit for Subsea Coatings Removal

June 2018

Our latest MultiJet high pressure pump unit is in build at our factory in Worcester. This diesel-engine-powered unit will be housed in a sound-reducing, DNV-compliant container with two sets of double access doors.More power for Middle East petrochemical customers

April 2018

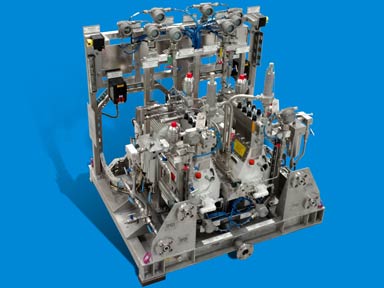

In build are the first four of our latest waterjetting pump units with uprated performance. In response to customer demand, this pump unit has been designed for tank and ...BOP testing system en route to drillship

February 2018

Commissioned by a major oil & gas well service company, this blowout preventer (BOP) testing system will be used to test the sealing arrangements of BOPs and will operate in an ATEX Zone 2, hazardous environment on-board a drillship.Venetian Bridge, Clacton Selective concrete removal, paint removal, and concrete preparation

January 2018

Moisture and corrosive salts have taken their toll on this iconic structure. The repair work started in October and the initial works saw the selective removal of large areas of degraded concrete.