Calder Supplies Complete Waterjetting and Cold Cutting System

Our ability to manufacture and supply everything you need for high pressure waterjetting has been demonstrated once again. Our customer placed great importance in being able to procure both the high pressure pump unit and the waterjetting accessories from one source to ensure compatibility of all the equipment. This complete waterjetting system will allow our customer to undertake surface preparation, hydrodemolition and cold cutting tasks. They will be supported by our Lifecycle Services team who are there for ad hoc advice, training, spares, and service.

Providing the high pressure water will be an industrial, trailer-mounted, emissions-compliant Calder MultiJet. Through our strong partnership with DERC Salotech, we are supplying the latest in cold cutting equipment technology for pipe, manhole, and tank cutting.

Our customers appreciate our ability to provide the complete package, including equipment, training, and dependable after-sales support. And this project amply demonstrates that ability. Additionally, our engineering department is currently designing a cutting tool to suit a unique application. This cutting tool is not available ‘off the shelf’, thus highlighting the benefits of working with one of the UK’s largest established high pressure equipment manufacturers.

High Pressure Water

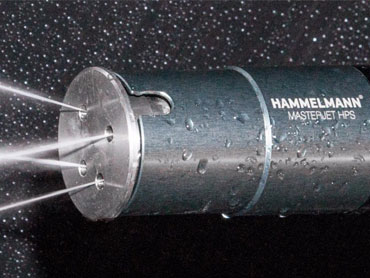

Our MultiJet features the very latest in low emissions technology with a Stage V engine. The pressure is provided by a Hammelmann pump – up to 2,800 bar in this instance. We have utilised Hammelmann pumps in much of our high pressure industrial equipment for over twenty five years. It offers excellent reliability and, through unique technology, a long service interval is achieved.

See why our customers prefer the MultiJet pump units.

Surface Prep and Hydrodemolition

Supplied with the MultiJet is our MasterJet rotary nozzle. Rotary surface prep nozzles convert the effectiveness of round jet nozzles into large area coverage performance through rotating nozzle heads. Various nozzle configurations and adjustable speeds open up many possibilities for surface treatment and hydrodemolition. The lightweight and compact design also enables work in areas that are difficult to access.

Cold Cutting

Cutting Assembly

This assembly incorporates the power head, hopper, abrasive storage, control panel and cutting head with nozzle. The assembly provides the cold cut and is used in conjunction with both the flexible magnetic track and the pipe bands.

Abrasive Cutting video

Flexible Magnetic Track

This track guides the cold cutting head to give accurate cutting whilst operated remotely. Much of our effort over recent years has been to increase operator safety and the best way to do that is to remove them from the area of operation. The track is used on both flat and cylindrical surfaces.

Pipe Bands

The scope of supply includes a range of pipe bands allowing the cutting of pipe diameters from 8” to 42”.

See the benefits of cold cutting.

Contact Us

Whatever your application, we are here to help. Please call us on +44 1905 751790 or email sales@calder.co.uk.