Hammelmann Pumps

Hammelmann UK Agent for over 20 Years

For over two decades, we’ve proudly served as the UK agent for Hammelmann pumps, driven by our unwavering belief in their exceptional quality. We integrate pumps from the Hammelmann HDP range into our high-pressure water jetting units. Similarly, for process pump packages, the Hammelmann Hampro pump range offers the ideal solution.

Our longstanding partnership with Hammelmann has led to numerous collaborative projects over the years. Our technical and sales teams receive comprehensive training at Hammelmann’s state-of-the-art production facility in Germany, ensuring they stay updated on the latest technologies and applications. Additionally, our sales team regularly participates in Hammelmann Innovation Days and agents’ conferences to remain current in the field.

Hammelmann pumps are built with precision engineering and high-quality materials, ensuring durability and longevity. They incorporate advanced technologies into their pump designs, such as efficient sealing systems and innovative hydraulic designs. These pumps are designed to withstand harsh operating conditions and demanding applications.

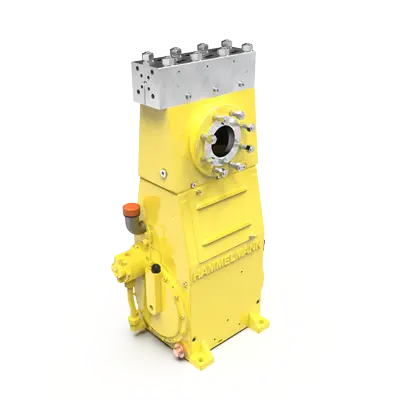

Key Features:

- Extended maintenance intervals for reduced downtime and lower lifetime operating costs.

- Vertical configuration for a compact pump skid design.

- Protection of pump components through weight-neutral running and low stress on the installation frame through the prevention of undesirable lateral oscillations.

Given our 20+ years’ experience of Hammelmann pumps, our large spares stockholding, and our highly trained and experienced service team, we are ideally placed to support you.

Industrial Pumps

The ‘yellow pump’, as it is often known, is a familiar sight in many industries. We incorporate this pump into our MultiJet high presure water jetting units. This popular product has both electric- and diesel-drive options, and it is either skid, trialer, crash frame, or container mounted. These units operate in safe areas or they are ATEX, NORSOK, or IECEx rated to operate safely in hazardous areas.

The Hammelmann industrial HDP range starts with the 30kW HDP 30 and goes up to the HDP 1200. The larger pump offers a performance ranging from 178 lpm at 3,000 bar up to a high flow performance of 2,968 lpm at 200 bar. These pumps are built to operate continuously at maximum duty.

- a stainless steel pump head free of alternating stress, bellows that form hermetic seal between the suction chamber and crank section.

- a choice of application specific seal assemblies.

- solid ceramic or tungsten carbide plungers.

- a choice of bronze (standard) or stainless steel suction chamber.

- crank section calculation by ‘Finite Element Method’ to ensure long working life under continuous load.

Process Pumps

We utilise the Hammelmann Hampro range of process pumps for applications such as chemical injection, boosting and circulation, and cooling. The Hampro pump also features heavily in our well service packages for BOP testing, pressure testing, and well stimulation.

Another process application for Hammelmann process plunger pumps is food processing. High pressure pasteurization drastically reduces the thermal impact on food, leaving valuable ingredients such as vitamins and natural colours and flavours unchanged.

We currently have a number of pump skids in build in the workshop that all feature Hammelmann Hampro process pumps. The latest order we have received is for an ATEX Zone 2-compliant well service pump package that will use the Hampro 200 series pump.

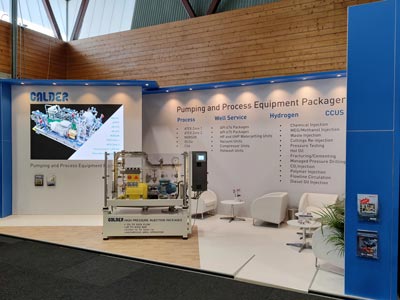

Hammelmann Pumps in Hazardous Areas

We package the Hammelmann pump for compliance with hazardous area specifications. Many packages are for operation in ATEX Zone 1 and Zone 2 hazardous environments. We have considerable experience designing pump skids to NORSOK standards for the Offshore Norway sector. Indeed, you will always find us exhibiting at the ONS exhibition in Stavanger, Norway as we have done since 2008. Pump systems for high pressure and hazardous area applications has been a major focus of our company for over 25 years. And the Hammelmann pump has been a huge part of our success.

Variable Stroke Technology

The Hampro Vario range of variable stroke reciprocating plunger pumps allow full flow control. These pumps allow a variable flow rate (0-100%) via adjustable stroke control, which removes the need for a VSD. Stroke adjustment is made automatically or manually, and while the pump is on or off load.

Hammelmann Accessories

Whether removing paint from ships’ hulls, cleaning pipes in petrochemical plants, or descaling tanks in production settings, the Calder high pressure pump units and Hammelmann accessories combine perfectly.

Surface Preparation

The Hammelmann Dockmate and SpiderJet are two surface preparation robots for large areas that are supported by the Calder MultiJet range of high pressure pump units. Couple these with our vacuum and water recycling technologies and safe, fast, efficient, and environmentally friendly paint removal with high pressure water is becoming the method of choice for coatings specialists.

Machines for floor, conveyor and grid cleaning, and road marking removal are cost-effective tools that produce high quality results. The MasterJet rotary surface preparation nozzle is a favourite among our customers.

Industrial Cleaning

Hammelmann manufacture a large range of nozzles, tank heads, and pipe cleaners. Pipe cleaning centralizers, hose reels, and non-man-entry robots are just a few of the many other accessories designed to make high pressure water safer and more efficient.

Zero Reaction Force Water Jetting

Removing the operator from the full reaction force encountered when using a hand-held jetting lance improves safety and efficiency. The repetitive recoil pressure can tire the waterjet operator, negatively impacting both well-being and productivity. Thus, both Calder and Hammelmann strive to offer solutions that reduce or eliminate operator involvement in both the reaction force and the work area.

Water Jetting Lances

Hammelmann lances are available for all your waterjetting applications.

- Dry shut guns up to 1,000 bar.

- Dump guns up to 3,000 bar.

- Open lances with electronic trigger up to 3,000.

- Single and double trigger versions available.

Support for Hammelmann Pumps

We provide full after-sales support for the entire life cycle of your pumping equipment. To suit the varying needs of our customers, we offer a range of spares and service packages from the ad hoc to a complete managed service. We design our service and support to minimize downtime and maximize equipment longevity.

To take the stress out of new equipment delivery, our team carries out installation and commissioning both onshore and offshore. Once commissioned, we offer safety, equipment familiarity, operation, and maintenance courses. These courses help to keep your colleagues safe and aid a trouble-free, long service life of the pumping equipment.

Contact the Team

Whatever your pumping application, we are here to help. Please call us on +44 1905 751790 or email sales@calder.co.uk to discuss your requirements.