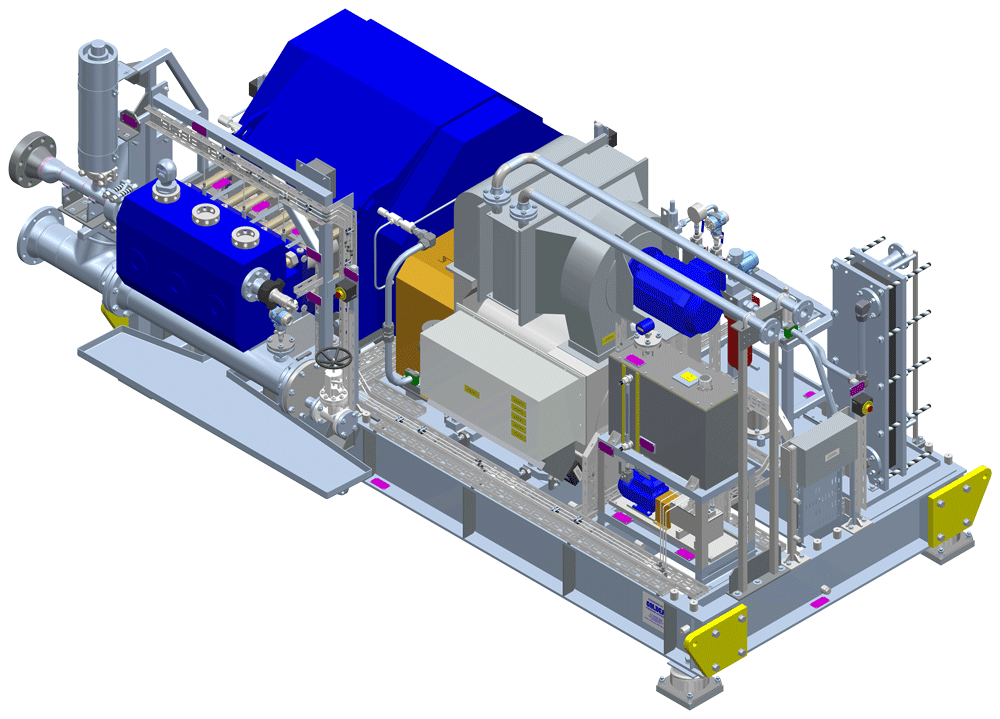

We are pleased to say we have received an order to design and manufacture a waste injection pump skid. This pump will operate in a Class 1, Div. 2 (Zone 2) Hazardous Area in the harsh conditions found in offshore Canadian waters. To allow installation onto an existing platform with limited deck space the unit will be modular in design. This will allow dismantling in Worcester and rebuilding in situ. We will carry out all design, build and testing at our factory in Worcester, UK.

Included as part of this project is a DA2 (Design Approach 2) Study. We use Design Approach 2 Studies to model and analyse the acoustics of positive displacement pumping systems and their pipework. This enables us to predict pulsations and vibrations in the system, either confirming that the equipment will operate within accepted parameters, or highlighting issues which we can then address.

We will conduct a full F.A.T. in our inhouse test facility and will include noise and vibration monitoring.

Our Waste Injection Pump Skid and CRI History

We have long been at the forefront of the development of waste injection pumping technology. We have designed many waste injection, often known as cuttings re-injection (CRI), packages for platforms with restricted space and/or access. This small foot-print pump unit case study addresses challenges presented on a platform with severe platform space constraints. In this modular pump skid video case study Dan discusses the solutions used in the design of a pump skid for a platform with particularly limited access.

This waste injection pump skid will incorporate the quality and reliability we have designed into these units over the last 25 years.

Talk with our Team

To talk through your waste injection project requirements, please call +44 1905 751790. Alternatively, email sales@calder.co.uk.