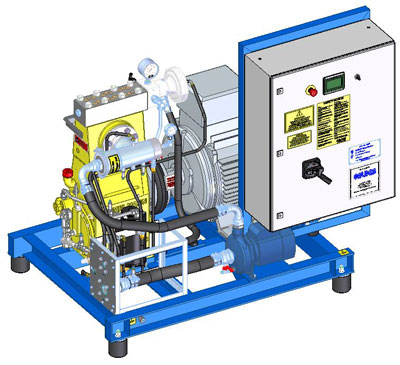

Currently in Build – High Pressure, Electric Drive Pump Skid

This pump skid will use high pressure water to clean dies used in animal feed processing. The unit is configured to pump 21 litres of water per minute at 2,600 bar. At the quotation stage, we ran a series of tests to establish the most efficient pressure and flow for the application. This ensures the dies are cleaned correctly with minimal water consumption.

Once the build is complete, the on-board control panel will include a monitoring unit with safety shutdowns for a range of critical parameters such as low lubricating oil pressure and high inlet water temperature. The control philosophy was written to suit the existing system into which the pump skid will be incorporated and our customer’s existing control process signal will be accommodated into the Calder control panel.

The design took into account a lack of access once the unit is installed. As such, unit handing and component positioning will ensure good maintenance access. The space-saving vertical pump design was a huge benefit for this project.

After the build process, the pump skid will undergo a F.A.T. This testing will be carried out at our purpose built test facilities. Customers can be present during testing. However, given the cost and time implications of getting here, we have a remote F.A.T. viewing option.

Design, PLC and HMI programming, build and testing is all done by us at our factory in Worcester. We will install and commission this pump package on site. Our lifecycle services team will then provide full training, spares, and service support to our customer.

Get in Touch

Whatever your production process pumping requirements, we are here to help. Please call us on +44 1905 751790 or email sales@calder.co.uk to discuss how we can help. Alternatively, discover our pumping solutions for a range industries.