the challenge

Ultra High Pressure High Temperature (uHPHT) is relatively new in the offshore industry. Operating conditions in uHPHT developments require equipment capable of achieving higher pressures and dealing with higher temperatures. High pressures are required to overcome friction losses in subsea pipelines where the well head can be up to 100 kms from the platform. To reach the greater water depths required to extract gas, pump systems are now being designed to operate at > 800 bar and increased temperatures > 150°C. The activities described present many new engineering challenges, resulting in the need for newly developed, bespoke pumping equipment.

the solution

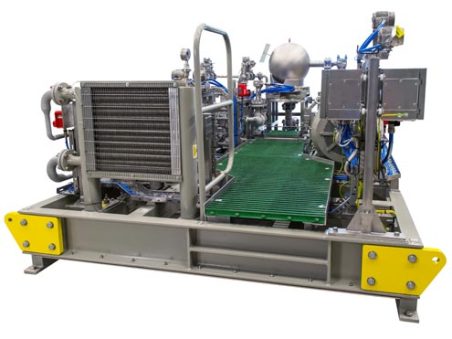

Calder designed, developed, manufactured and tested two bespoke high pressure methanol injection pump skid packages in order to inhibit and prevent hydrate formation in gas flowlines. Hydrate prevention becomes more challenging at greater water depths. Hydrates are ice-like solids that can form in flowlines at high pressure and low temperature conditions. These can result in large plugs (blockages) which can be tens, or even hundreds, of metres long. Hydrate formation can cause serious and sometimes dangerous problems for drilling and production processes.

The units were designed specifically for use in uHPHT applications and with safety and reliability paramount. Careful component selection, innovative design and engineering, a vastly experienced build team, and the latest test facilities ensure these units will offer years of safe, reliable service.

For more about our methanol injection packages.